Water treatment screening is a crucial first step in ensuring your household tap water is of the highest quality. When water from sources like rivers, lakes, or even wastewater is treated, removing large contaminants is essential. This process helps protect the finer, more delicate filtration systems that follow from being clogged or damaged by sizable debris. Screening ranges from the removal of leaves and twigs all the way to minuscule particulates that can disrupt the water treatment process.

Efficient screening contributes significantly to the overall effectiveness of the water treatment system. By selecting the right screening type, such as fine, medium, or coarse screens, you can prevent a variety of problems down the line. Moreover, proper maintenance of these screens is of utmost importance to ensure they perform their role reliably. This involves routine checks and timely repairs, which safeguard the efficiency of water treatment plants. Staying well-informed and adhering to environmental regulations is not only good practice, it’s a necessary part of responsible water treatment management, keeping groundwater sources and the environment safe from pollution.

Key Takeaways

- Proper screening is foundational in protecting water treatment processes.

- Choosing and maintaining the correct screen type ensures efficiency and safety.

- Compliance with regulations preserves water quality and environmental health.

Understanding Water Treatment Screening

When you turn on the tap in your home, you expect clean water. But what ensures its quality before it gets to you? That’s where water treatment screening plays a pivotal role.

The Importance of Screening in Water Quality

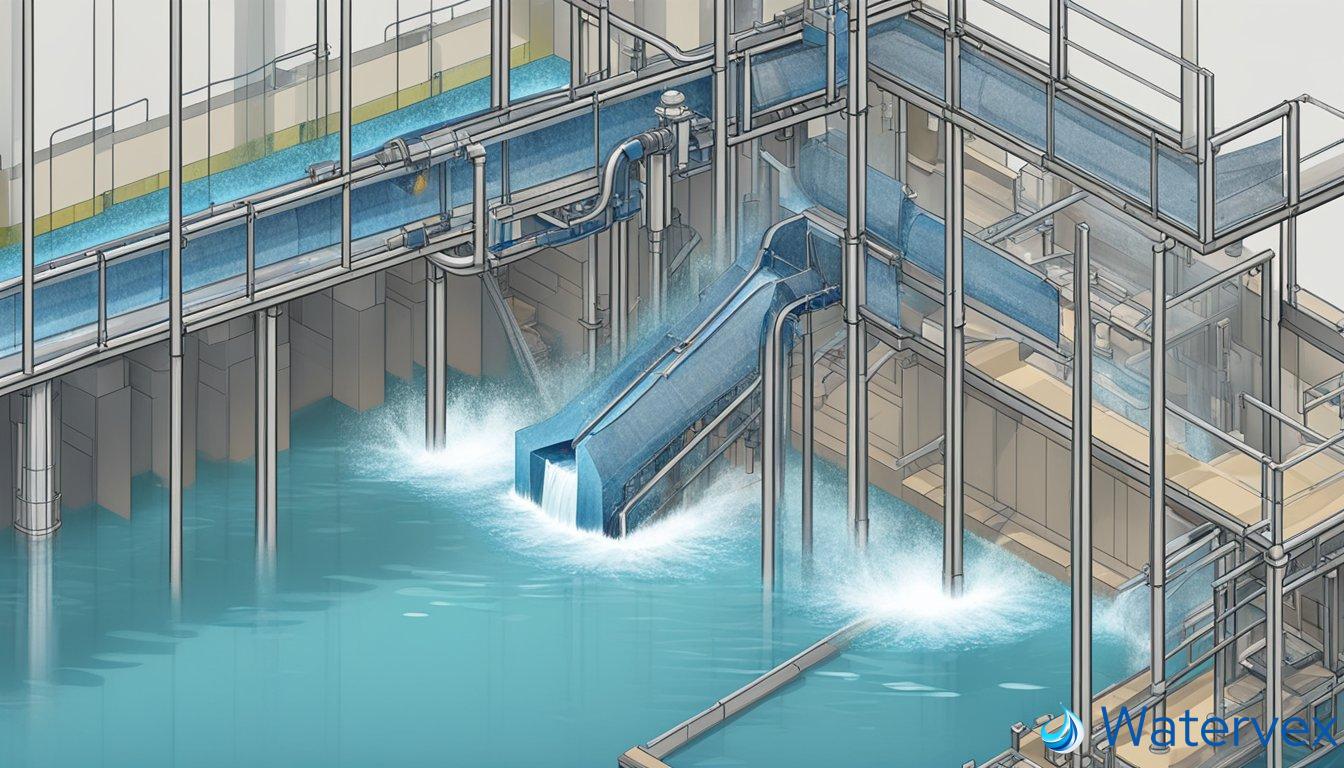

Screening is essential; it’s the front line defender in the water treatment process. Imagine screens as goalkeepers, preventing unwanted materials such as leaves, twigs, and other large debris from progressing further into the water supply system. Without screening, this debris could clog and damage downstream treatment equipment, reducing efficiency and potentially compromising water quality. Effective screening is key to protecting subsequent filtration and sedimentation processes crucial for delivering safe drinking water to your home.

Common Screening Systems for Residential Use

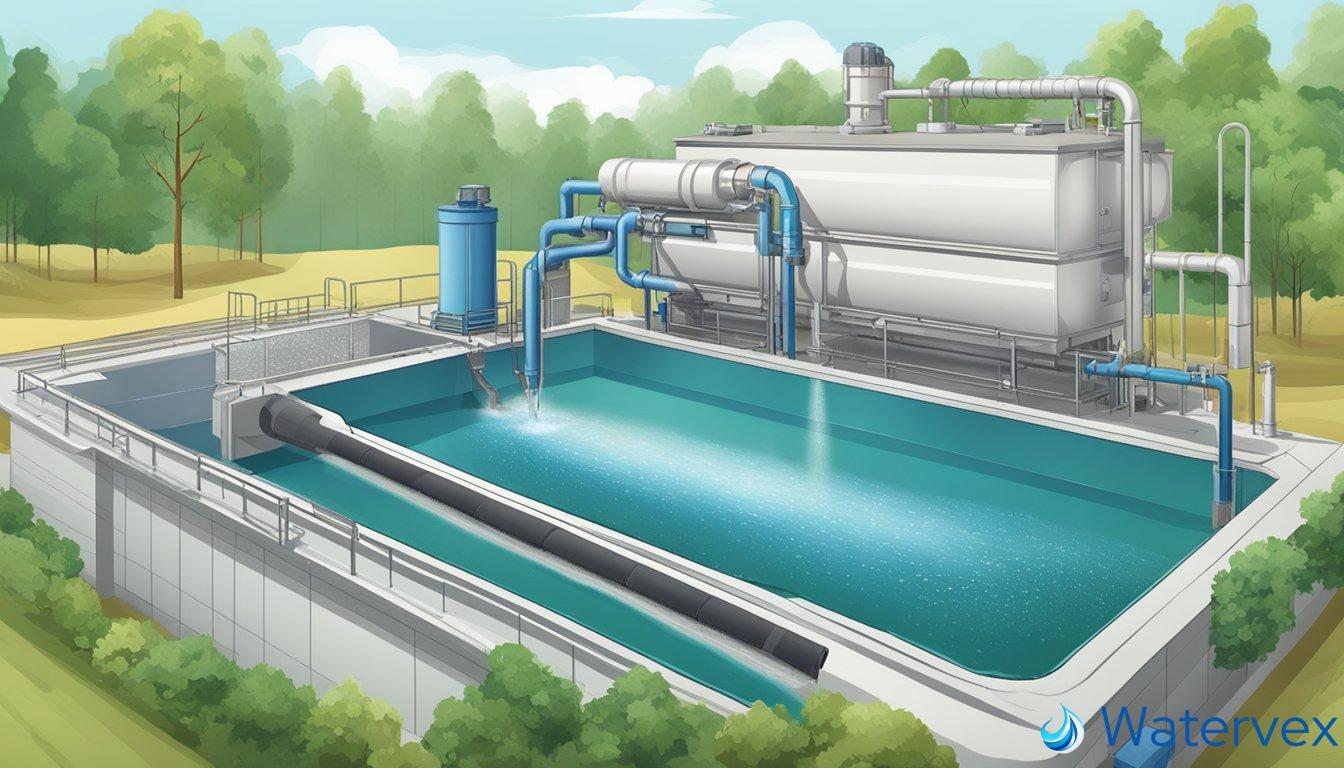

In the residential context, screening systems vary greatly but they all serve one purpose: to keep solids out of your water. For instance, a simple mesh screen at your faucet is a basic form of screening aimed at trapping sediment. More advanced home systems might include drum screens or disk filters, designed to provide finer levels of filtration and ensure even tiny particles are intercepted. These systems are integral for maintaining water quality and can help prolong the lifespan of household appliances by preventing scale buildup from hard water minerals like calcium and magnesium.

Choosing the right screening system often depends on your water source and specific contaminants. Beyond the basics, each system has its pros and cons when it comes to dealing with debris size and type. Regular maintenance of these screens, including cleaning and replacement, also factors into keeping your water clean and safe.

Remember, screening is your water’s first line of defense, and choosing the right system is crucial for ensuring the quality and safety of the water in your home.

Screen Types and Their Functions

In water treatment, understanding the types of screens and their specific functions is crucial for ensuring the safety and quality of your water. These tools are the front line of defense in the water treatment process.

Fine vs. Coarse Screens

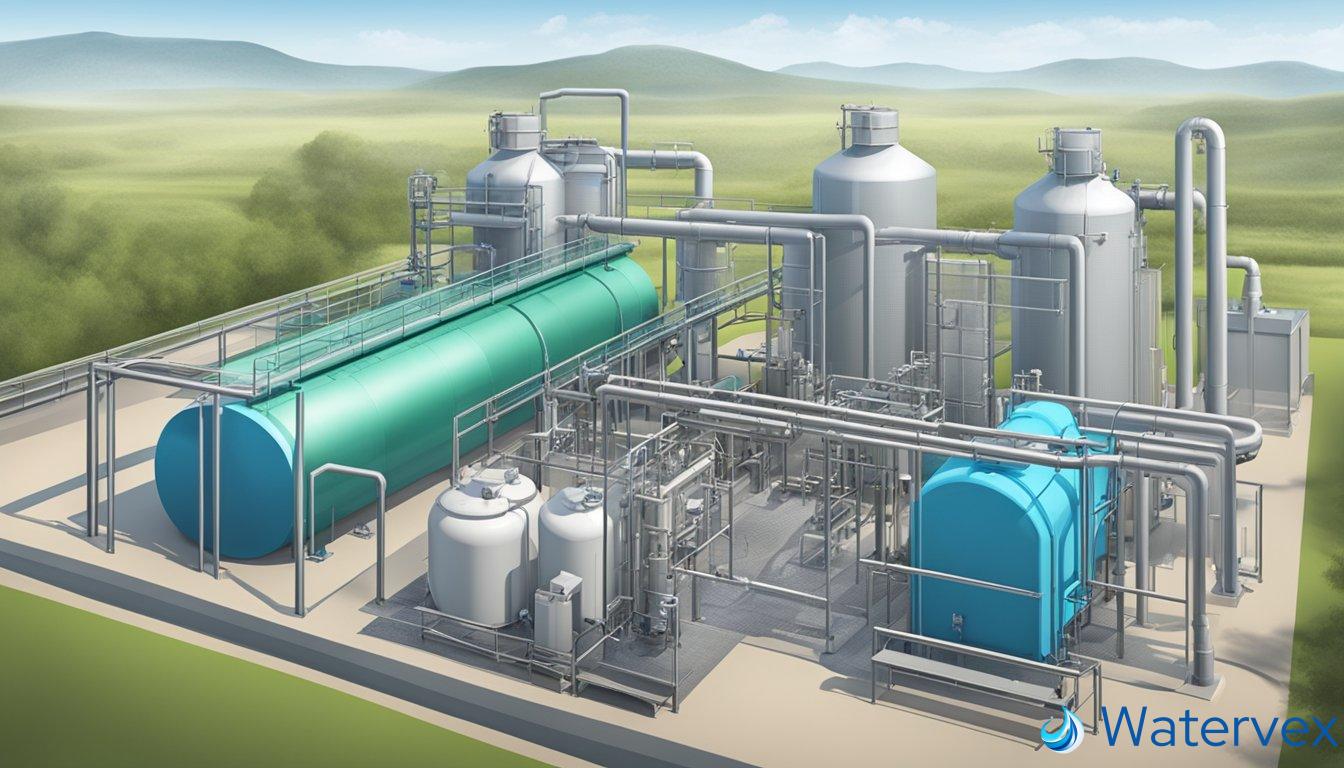

Fine screens are critical in filtering out small particles, with openings typically ranging from 0.5 to 6 mm. They are particularly effective at removing organic matter and other small debris that could impede the treatment process. Fine screens not only safeguard the intricate machinery downstream but also improve the overall efficiency of the treatment system by removing finer particulates early on. These screens are often employed in municipal wastewater treatment plants to ensure that the water quality meets regulatory standards.

In contrast, coarse screens have larger openings and are designed to capture the bigger solids such as rags, plastics, and other substantial objects. These are usually the first line of defense in a wastewater treatment facility, tasked with protecting subsequent stages from clogging or damage. Coarse screens’ robust nature means they are well-suited to deal with the diverse types of debris typically found in untreated water.

Specialized Equipment for Wastewater Treatment

Among the specialized equipment for wastewater treatment, drum screens stand out. These screens are cylindrically shaped and rotate to separate solids from the water as it flows through. Their design allows for continuous operation and is effective for both fine and coarse screening, adaptable to various waste loads. Drum screens are a sophisticated choice for those aiming to enhance the efficiency and reliability of their wastewater treatment system.

Wastewater screens are not one-size-fits-all and must be selected based on the specific needs of your treatment plant. The choice between a fine screen and a coarse screen will depend on factors such as the expected size and type of debris in the wastewater, as well as the desired quality of the treated water. With the right screens in place, you can be assured that your water treatment system is up to the task of providing safe, clean water for your family or home.

Selection and Maintenance of Screening Systems

When selecting screens for water treatment and ensuring their maintenance, you’re looking at two main goals: the right fit for your specific needs and cost-effective operations.

Criteria for Choosing the Right Screens

Functionality Comes First: It’s imperative that the screens you choose effectively remove the types of debris commonly encountered in your water. This can range from leaves and twigs to smaller particles like sand. Choosing the correct mesh size is essential for the optimal performance of screens, this being contingent on the peculiarities of your water source.

Compatibility with Existing Infrastructure: The new screens should be congruous with your current water treatment setup. This means considering the dimensions and installation requirements of the screens vis-à-vis your system. A seamless integration promises not just improved efficiencies but also a potential decrease in equipment maintenance costs.

Maintaining Efficiency and Reducing Costs

Regular Check-ups: To keep your screening system working at its best, routine maintenance is non-negotiable. An inspection schedule helps spot issues like wear or clogging early on. Proactively addressing these problems can prevent more costly repairs or even replacements down the line.

Efficient Practices: Keeping up with maintenance doesn’t only prolong the lifespan of the screens but is also kind to your wallet. Cleaning and repairs, when carried out judiciously, assure that the screens function efficiently, thus lowering energy costs and safeguarding downstream water treatment technologies.

- Regular maintenance checks

- Prompt cleaning and repairs

- Monitoring for wear and damage

- Ensuring compatibility with other equipment

To echo the sentiment, by being proactive and thoughtful about your screening systems, you establish a foundation for sustainable water treatment practices that prioritize efficiency and cost-effectiveness. Remember, the right selection paired with diligent maintenance can lead to substantial dividends over time.

Environmental and Regulatory Considerations

When navigating the complex terrain of water treatment screening, understanding the intricate relationship between environmental protection and regulatory measures is crucial. If you manage an industrial wastewater treatment facility, it’s imperative that you identify contaminants of concern that may be present in your effluent. These contaminants could range from organic solids to heavy metals, depending on the nature of your industry.

Regulations such as the Clean Water Act in the United States set specific limits on pollutants in water to protect human health and the environment. Your facility’s effluent must meet these standards before it can be released back into the environment. Non-compliance can lead to hefty fines or even plant shutdowns, so thorough screening processes must be in place to prevent pollutants from slipping through the cracks.

Imagine a scenario where larger materials, like rags or plastics, damage downstream equipment. This is where having proper screening as a preliminary step in the wastewater treatment process comes into play. Efficient screening technologies will remove these materials and considerably reduce maintenance costs and downtimes.

For instance, Water Environment Federation provides a detailed PDF on Liquid Stream Fundamentals: Screening, which can serve as an excellent guide for understanding how screening works within your operations.

However, it’s not just about the technology but also about adapting to evolving regulations. EPA’s Environmental Justice in Regulatory Analysis highlights the importance of considering how your water treatment processes affect local communities, particularly vulnerable populations. You must factor in community impact, both from an environmental and regulatory standpoint when designing and operating your facility.

To sum it up, always stay informed about the latest regulatory guidelines, invest in robust screening processes, and consider the broader environmental impacts of your wastewater treatment. Your efforts are not only a regulatory obligation but also a commitment to safeguarding both the environment and the community.