Protecting your water softener from freezing temperatures is essential for maintaining the quality and longevity of your water treatment system. When water turns to ice, it expands, which can potentially cause cracks and significant damage to the internal components of your water softener. This can not only be costly in terms of repairs or replacements, but it can also lead to interruptions in having access to softened water when you need it most.

To safeguard your water softener from the harsh cold, certain preventative measures should be taken before the onset of freezing temperatures. Insulating your water softener can be a good strategy, as it keeps the system warm and reduces the risk of the water inside from freezing. There are specific techniques for insulating and winterizing that are designed to provide optimal protection, such as using insulated blankets or building an insulating box around the water softener’s tank.

Key Takeaways

- Freezing can cause significant damage to water softeners

- Insulation methods are crucial for freeze protection

- Prevention should occur before the cold sets in

Why Is Freeze Protection Crucial for Water Softeners?

Freeze protection is essential to maintain the functional integrity of your water softener system during cold weather.

Understanding Water Softener Components

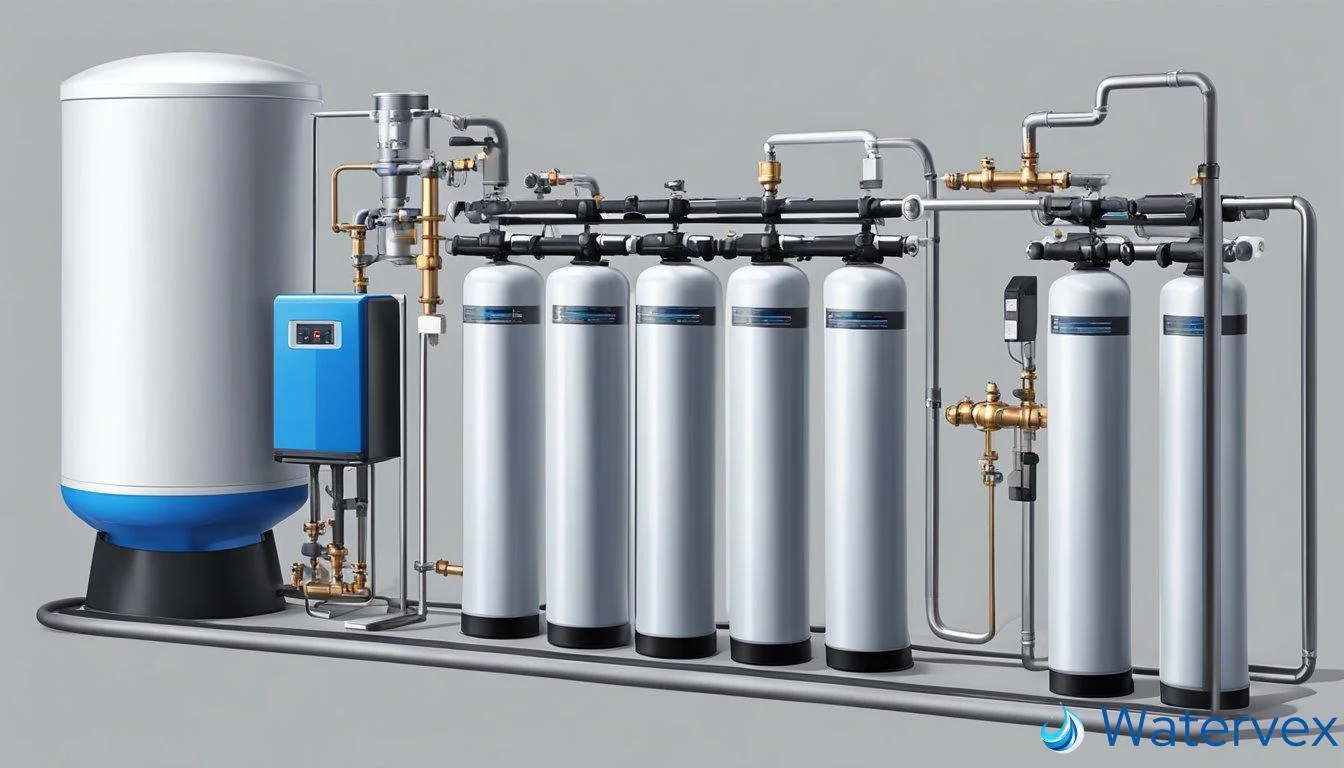

Your water softener is a composite system that typically includes a mineral tank, brine tank, and various plumbing connections. The mineral tank contains resin beads which are crucial for the ion exchange process that softens your water. The brine tank holds a highly concentrated solution of salt or potassium that regenerates the resin. This interlinked system relies on water flow and can be severely disrupted by freezing conditions.

Risks of Not Protecting Your Water Softener

If your water softener freezes, the consequences can range from frozen pipes that hinder water flow to burst pipes that cause extensive leaks. The softener tank, brine tank, and the media tank can all sustain damage from ice expansion. Such damage disrupts water softener operation and may result in costly repairs or even the need to replace the entire unit. The key to prevention lies in insulating the system and ensuring it’s not exposed to temperatures that could lead to a freeze.

What Are the Best Methods to Prevent a Water Softener from Freezing?

With winter’s chill, protecting your water softener from freezing is critical to maintain its efficiency and longevity. Here we’ll explore targeted strategies to keep your softener safe from the icy grip of cold weather.

Insulation Techniques for Softeners

To insulate your water softener, start with a pipe insulation wrap around both the tanks and the pipes. This helps retain heat and prevent freezing. Plumbing insulation, such as foam tubes, can be bought at any home improvement store and is easy to apply. Make sure to secure the insulation with durable materials, such as zip ties, to ensure it stays intact throughout the colder months.

Insulation Cover:

An insulation cover can act as an additional layer of protection, especially for the parts of your water softener that are most susceptible to freezing. The cover should be weather-resistant and capable of withstanding low temperatures. It’s best to choose a cover made of materials known for their insulating properties.

Heat Sources and Safe Operation

Another method to prevent freezing is to introduce a gentle heat source near the water softener. A space heater can be effective but must be used with caution. Maintain a safe distance between the heater and the softener and never leave the heater operating unattended. Always ensure proper ventilation and adhere strictly to the manufacturer’s safety instructions.

Location Matters:

Consider the location of your water softener; it should reside in a place that minimizes exposure to freezing temperatures. If possible, install the water softener in a heated area of your home. This could be near a furnace or other internal heat source to provide ambient warmth, reducing the risk of freezing significantly.

When Should You Take Action to Shield Your Water Softener from Cold Weather?

As temperatures begin to fall, it’s crucial to prepare your water softener to prevent damage from freezing. Initiating winterization processes and maintaining consistent care will ensure your system remains functional and efficient.

Timing Your Winterization Efforts

Before the first frost hits is the optimal time to begin the winterization of your water treatment equipment. Scheduling annual winterization maintenance in early fall, such as October or November, can be an effective strategy to avoid rush and potential oversight. If you own a vacation home or live in an unheated location, it’s recommended to winterize your system before you depart or when consistently low temperatures are forecasted.

- Check weather forecasts vigilantly as winter approaches.

- Unplug your water softener and initiate a manual regeneration cycle to clear out water.

- Consider the specific winterization needs based on where your water softener is located. If outside or in an unheated space, safeguarding against freezing is imperative.

Maintaining Water Softener Health Throughout the Winter

To uphold your system’s health during winter, ensure that heating system components are checked and functioning properly, as this will minimize the risk of your building plumbing becoming a cold spot. If your water softener is installed in a space prone to cold weather exposure or flooding:

- Drain lines should be cleared to prevent freezing.

- Conduct sanitizing, cleaning, and recharge cycles regularly.

- Shut down and drain the system if water usage will be minimal or if you are leaving your home for an extended period.

Regularly regenerate your water softener, but be extra cautious about the freeze protection while doing so, as the process involves water movement that could be at risk of freezing. Being proactive with winterization could save you from costly repairs and ensure consistent water quality throughout the colder months.